When it comes to drill bits, sharpness is king. But what exactly makes a drill bit cut perfectly? From the physics of cutting angles to the material science behind durability, the performance of a drill bit is a finely tuned balance of design, materials, and engineering.

The Physics of Cutting

At the heart of a drill bit’s performance is its ability to effectively penetrate a material. This involves two main factors: cutting angle and feed force.

- Cutting Angle: The cutting edges of a drill bit, known as the lips, play a critical role in determining how well it cuts. For example, a 118-degree point angle is ideal for general-purpose drilling in softer materials, while a 135-degree point angle is better suited for harder materials like steel, as it reduces wandering and improves stability.

- Feed Force: The amount of pressure applied while drilling directly impacts the bit’s cutting efficiency. Too little pressure can lead to slipping, while too much can cause overheating and premature wear.

Material Science: Strength Meets Durability

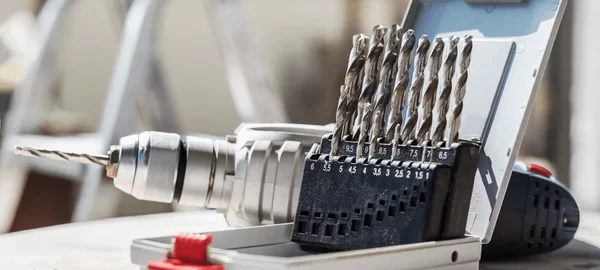

The materials used to manufacture a drill bit are just as important as its design. High-performance drill bits are crafted from advanced materials that balance hardness, toughness, and heat resistance.

- High-Speed Steel (HSS): A standard for many applications, HSS offers a good balance of durability and cost-effectiveness.

- Cobalt Alloys: Ideal for drilling through hard metals, cobalt drill bits resist heat and maintain their sharpness longer.

- Carbide-Tipped Bits: These bits are extremely hard and capable of cutting through the toughest materials, including masonry and concrete.

- Diamond-Coated Bits: For ultra-precise work on hard surfaces like glass and ceramics, diamond coatings provide unmatched sharpness and wear resistance.

Heat and Friction: The Hidden Challenges

One of the biggest enemies of sharpness is heat. As a drill bit cuts through material, friction generates heat, which can dull the cutting edges over time. That’s why many high-performance drill bits include coatings designed to reduce friction and dissipate heat, such as titanium nitride or black oxide.

Maintenance: Keeping the Edge

Even the best drill bits require proper care to maintain their sharpness. Regular sharpening, cleaning, and proper storage can extend the life of a drill bit significantly. Sharpening tools or professional sharpening services can restore cutting edges to like-new condition.

Engineering Innovations in Drill Bits

Modern engineering has brought about innovations like split-point tips, which help reduce wandering, and flute designs that improve chip evacuation. These advancements ensure that drill bits not only cut sharply but also perform consistently under various conditions.

Conclusion

The science of sharpness is a fascinating blend of physics, material science, and engineering. A drill bit’s ability to cut perfectly depends on its design, the materials it’s made from, and how it’s maintained. By understanding these factors, professionals and DIYers alike can achieve better results and extend the life of their tools.

Whether you’re drilling into softwood or hardened steel, the right drill bit—and a little science—makes all the difference.

You can also visit our partner site at www.drillbitsusa.com for more information.